He Operates Molding Machines. But He Can’t See Them.

(Originally published in the New York Times by Patricia R. Olsen on 9/28/2018)

Jay Browder, 43, is a machine operator at Alphapointe in Kansas City, Mo.

When did you become blind?

I lost my sight at 19 when I got shot in the face in a gun accident. I had left high school early to go to work, but losing my vision gave me the motivation to enter a program to get my degree.

I was the only blind student at the school. I needed help with math, but I taped the other classes and studied from the tapes. I was on the bus when I got the call that I’d passed, and I almost got up and ran off I was so happy.

Then I attended a community college and transferred to the University of Detroit Mercy and got a bachelor’s in computer information systems.

What’s your job?

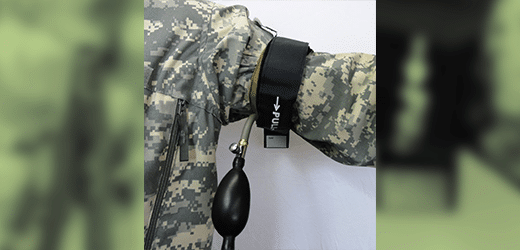

I run three microinjection molding machines. Two produce plastic barrels and inside parts for the Skilcraft U.S. Government pen, for government personnel, and one produces parts for the Skilcraft B3 Aviator pen, for military pilots. I also run two larger injection molding machines that produce prescription pill bottles for the pharmaceutical industry, and spray bottles.

Whom do you work for?

Alphapointe is a nonprofit associated with the government’s AbilityOne program, which creates employment for people who are blind. National Industries for the Blind, a nonprofit designated by AbilityOne to work with it, provides the federal projects I’m involved with. I work primarily for the office products and pharmaceutical products departments here.

How do you operate those machines?

Very carefully. There’s a science to it, to keep up with the work and do a good job, especially with no vision. It’s mind over matter. I often tell myself: “It’s me versus the machine. Who’s going to win?” I have to stay on top of things and make sure I don’t make mistakes.

But the machines are also adapted for us. As an example, one machine has a protective case with a handle to open it. Also, I know where the buttons and the tactile labels are, and we follow emergency procedures.

If a pharmaceutical container gets stuck in the machine, rather than try to fix it myself, I sound an alert. Often, the person who comes to fix it is a blind co-worker who has been trained on jams.

But the machines are also adapted for us. As an example, one machine has a protective case with a handle to open it. Also, I know where the buttons and the tactile labels are, and we follow emergency procedures.

If a pharmaceutical container gets stuck in the machine, rather than try to fix it myself, I sound an alert. Often, the person who comes to fix it is a blind co-worker who has been trained on jams.

Does the work get tedious?

No, because I’m always asking to learn new machines. I joke that it makes me marketable, but really, I just like to help. The more machines I know, the more the supervisors can move me around. I’ve also done product assembly and packaging. The veteran workers here have passed on tips like slightly tipping a box to affix a label and then feeling with your fingers to line it up with the edge. I also try to envision what the box looks like.

What is your work background?

I worked at Citibank here in a call center for several years and then was a stay-at-home dad for three years raising my daughter. After that I found a job in Alphapointe’s call center and eventually moved over. I’ve been with the organization for three years in December.

How do you think of blindness in the workplace?

It’s fascinating that my co-workers and I are able to do things like this. Some of my colleagues have been blind their whole life. They’ve never seen another person or driven a car, but they can do this work and do it well.

It encourages me and motivates me to come in every day and work hard.